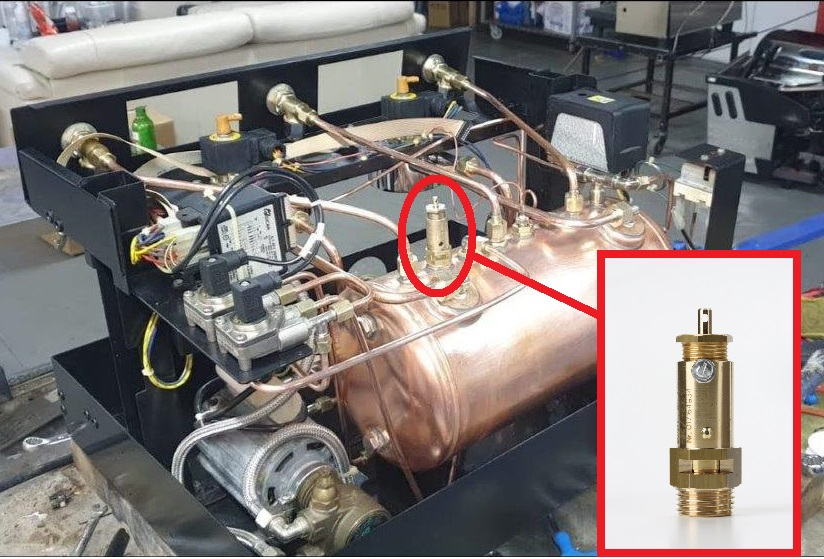

Safety Valve model D7/S (PN 60)

DN8 (1/4") - DN10 (3/8") | Orifice 7mm

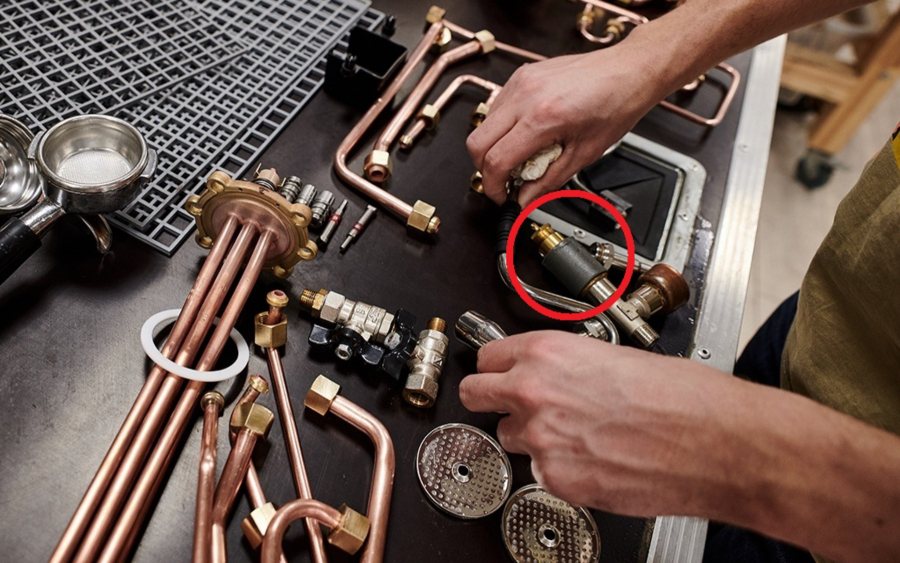

The use of copper alloys in industrial coffee machines addresses specific needs in the industry, including:

However, this choice also requires ensuring compliance with regulations, such as MOCA certification, to avoid contamination in the coffee and ensure the safety of the final product.

In the coffee machine industry, safety valves (PSV, Pressure Safety Valves) are essential for protecting vessels, such as boilers or pressure tanks in coffee machines, from overpressure that could cause structural damage or pose a danger to the operator. Coffee machines, particularly professional ones, operate with a system that heats water under pressure to extract coffee through the espresso method. During the heating process, the water is brought to very high temperatures, and any accumulation of steam and internal pressure is carefully monitored. If the pressure exceeds the safety limit, the PSV activates automatically, allowing the excess steam to escape in a controlled manner.

Safety valves are typically installed on the boiler or steam storage vessel, and it is common to find them at strategic points in the system to ensure that the entire system is protected. Installing a PSV in coffee machines is critical to prevent explosions or damage to the machine components caused by excessive pressure, while ensuring safe and optimal operation. Additionally, the use of safety valves ensures that the system complies with safety regulations and necessary certifications, protecting both the integrity of the machinery and the safety of the operators.

The MOCA certification (Materials and Objects in Contact with Food) is particularly critical for coffee machines, as it ensures that all components in contact with coffee, including safety valves, are safe and do not release harmful substances into the liquid. In an industry where food safety is paramount, this certification ensures that machines comply with European regulations and do not compromise consumer health.

Alongside this compliance, there is an increasing demand for cheap products, often utilizing copper alloys instead of stainless steel to reduce costs and benefit from the physical-mechanical properties of the material. Although copper is a suitable material for many applications, it is not always MOCA-compliant, as it can react with hot liquids or other substances, risking contamination of the coffee with heavy metals or other chemicals.

Our valves are made with 100% Italian materials, ensuring complete traceability and the highest quality. All components comply with FDA regulations, guaranteeing safety and reliability in contact with food and beverages.

Upon request, we offer MOCA certification (Materials and Objects in Contact with Food), certifying the suitability of the materials, tested in certified laboratories, for use in winemaking and brewing processes. This guarantees maximum protection against contamination while adhering to the most stringent food industry standards.

To meet the growing demand for safety valves that meet the needs of the coffee machine industry, Nuova General has developed a line of brass CW510L "LF" (lead-free), low-lead valves, compliant with MOCA as demonstrated by tests conducted in certified laboratories, ensuring safety and optimal performance in contact with food and beverages.

The MOCA certification (D.E. 1935/2004) is essential for safety valves installed in coffee machines, as it ensures that the materials in contact with coffee or other beverages are safe and comply with European health and food safety regulations. The MOCA certification guarantees that the valves do not release harmful substances into the fluid that comes into contact with the consumer, preventing chemical or physical contamination. For coffee machines, where the quality and safety of the final product are crucial, this certification becomes an indispensable requirement to ensure optimal performance and user protection.

DN8 (1/4") - DN10 (3/8") | Orifice 7mm

DN8 (1/4") - DN10 (3/8") | Orifice 7mm

DN10 (3/8") - DN15 (1/2") | Orifice 10mm

Choosing a Nuova General Instruments safety valve means relying on a product designed and manufactured according to the highest quality and safety standards. In addition to our years of experience and continuous focus on innovation, we offer a range of dedicated services to support our customers at every stage, from product selection to after-sales assistance:

• ⚡ Fast Delivery: Standard production within 10 business days, with a Fast Track option for shipments in just 5 days.

• 📦 Flexible Lot Sizes: We provide both single valves and large batches up to 1000 units, always ensuring top quality.

• 🎨 Customization: Laser marking, colored caps for calibration identification, and removable barcode labels for simplified management.

• ✅ Third-Party Testing: Option to obtain 3.2 test certificates from prestigious organizations such as INAIL, TUV, RINA, LLOYD, DNV, and ABS.

• 📄 Online Certificates: Immediate and unlimited access to technical documentation of the valves through our dedicated portal.

• 🛠️ Product Samples: Ability to test our valves before placing regular orders, with specialized technical support.