Learn More > What is a Safety Valve

What is a Safety Valve

Terminology of Safety Valves

The terminology surrounding safety valves can sometimes be confusing due to the diverse range of pressure relief devices available and the differing standards across various regions. In essence, both "safety valve" and "safety relief valve" are broad terms used to describe pressure relief devices designed to prevent excessive internal fluid pressure buildup.

Across different national standards, specific definitions are provided for terms associated with safety valves. Notably, there are significant differences between the terminologies used in the USA and Europe. For instance, what is termed a "safety valve" in Europe may be referred to as a "safety relief valve" or "pressure relief valve" in the USA. Additionally, the term "safety valve" in the USA often specifically denotes the full-lift type of safety valve commonly used in Europe.

Due to these variations in terminology and standards, different designs of safety valves are required to meet the specific requirements outlined by each region's regulations. Manufacturers must ensure compliance with these standards to ensure the safe and effective operation of their pressure relief systems.

In the realm of industrial safety, pressure relief valves play a crucial role in safeguarding equipment and personnel from the hazards of excessive pressure buildup within systems. To ensure consistency and reliability in their design and application, various standards have been established by organizations such as the American Society of Mechanical Engineers (ASME), the American National Standards Institute (ANSI), and the European Committee for Standardization (CEN).

The ASME/ANSI PTC25.3 standards, applicable in the USA, define several generic terms related to pressure relief valves. These include the "pressure relief valve" (PRV), which is characterized by its spring-loaded mechanism designed to open rapidly to relieve excess pressure. This valve type may exhibit a rapid-opening "pop" action or open in proportion to the increase in pressure over the opening pressure. It encompasses safety valves, relief valves, and safety relief valves, serving various applications with compressible or incompressible fluids.

Among these, the "safety valve" (PSV) stands out as a pressure relief valve actuated by inlet static pressure, known for its rapid opening or "pop" action. Primarily used with compressible gases, safety valves find extensive application in steam and gas services, providing vital protection against overpressure scenarios. Additionally, they may be utilized in process applications to safeguard equipment or prevent product spoilage.

In contrast, the European standard EN ISO 4126-1 offers a distinct definition for the "safety valve." According to this standard, a safety valve is a device that automatically discharges fluid to prevent a predetermined safe pressure from being exceeded. Unlike other types of pressure relief valves, a safety valve operates solely based on the energy of the fluid itself, closing once normal pressure conditions are restored.

The key distinction between these standards lies in their terminology and focus. While the ASME/ANSI standards provide a comprehensive framework for various types of pressure relief valves, emphasizing their operational characteristics, the European standard prioritizes the functional aspect of safety valves in preventing pressure exceedance.

In summary, both the ASME/ANSI PTC25.3 and European EN ISO 4126-1 standards offer valuable guidance on pressure relief valve design and application. Understanding the nuances of these standards is essential for ensuring compliance and selecting the most suitable pressure relief valves for specific industrial applications, ultimately enhancing safety and reliability in industrial operations.

History of Safety Valves

Since ancient times, humanity's ability to harness the power of steam has been met with the recognition of the critical need for safety measures. Dating back over 2000 years, the Chinese ingeniously employed cauldrons with hinged lids, pioneering a relatively safer method for steam production. This early innovation laid the groundwork for future advancements in steam technology.

By the 14th century, chemists began implementing safety devices on pressurized vessels, starting with conical plugs and later transitioning to compressed springs. However, it wasn't until the early 19th century that the importance of safety mechanisms truly came to the forefront. Tragically, boiler explosions aboard ships and locomotives were all too common, often resulting from faulty safety devices.

This dire need for improved safety spurred the development of the first safety relief valves. In 1848, Charles Retchie's invention of the accumulation chamber marked a significant advancement in safety valve technology. This innovation increased the compression surface within safety valves, allowing them to open rapidly within a narrow overpressure margin.

Today, stringent health and safety regulations compel most pressure users to integrate safety devices and precautions into their facilities, plants, and processes. These measures serve to prevent dangerous conditions and safeguard both life and property. The primary function of a safety valve remains clear: to protect against catastrophic failures caused by overpressure.

As we reflect on the evolution of pressure safety, from the rudimentary cauldrons of ancient times to the sophisticated safety valves of today, one thing remains constant: the importance of prioritizing safety in all pressure-related endeavours. By embracing technological advancements and adhering to rigorous safety standards, we can ensure that pressure continues to be harnessed safely and effectively for generations to come.

Safety valves function

In industrial settings, where processes involve high pressures and temperatures, ensuring safety is paramount. Among the primary devices utilized for preventing overpressure and potential catastrophic failures are safety valves. These valves are designed to release a controlled volume of fluid from within a system when a predetermined maximum pressure is reached, thereby reducing excess pressure in a safe manner.

Safety valves serve as critical safeguards, especially in scenarios where they might be the last line of defence against disastrous outcomes resulting from overpressure conditions. Therefore, it's imperative that these devices are not only installed wherever the maximum allowable working pressure (MAWP) of a system or pressure-containing vessel is likely to be exceeded but also capable of operating reliably under all possible conditions.

Safety valves are employed in various process operations to prevent product damage caused by excess pressure.

Pressure excess can arise from a multitude of circumstances, like:

- Pressure controller or regulator failure

- Plant exposed to fire

- Failure of the cooling system or changes in ambient temperature leading to fluid expansion

- Heat exchanger tube failures

- Increase of flow rate due to a wrongly closed or opened isolation valve

- Chemical fluid reactions

In light of these potential hazards, the installation and proper functioning of safety valves are crucial for maintaining operational integrity and ensuring the safety of personnel and equipment. By effectively mitigating the risks associated with overpressure conditions, safety valves play an indispensable role in safeguarding industrial processes and preventing costly accidents.

Safety valves serve as vital guardians, protecting against the devastating consequences of overpressure events and upholding safety standards in high-risk environments. As industries continue to evolve, prioritizing the implementation and maintenance of robust safety measures, including safety valves, remains essential for promoting a safe and sustainable working environment.

Interested in learning more about sizing safety valves? Click here to find out!

Safety valve design

Commonly referred to as 'standard' or 'conventional safety valves, these devices offer simple yet reliable self-acting protection mechanisms.

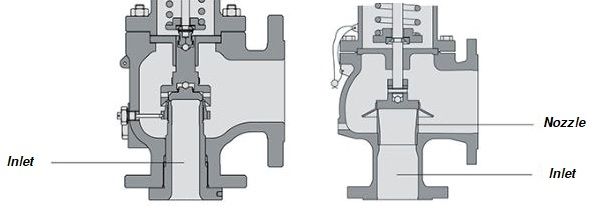

At the heart of the design lies a right-angle pattern valve body, featuring an inlet connection or nozzle mounted on the pressure-containing system. The outlet connection, typically screwed or flanged, facilitates connection to a piped discharge system. However, in certain applications like compressed air systems, safety valves may vent fluid directly to the atmosphere, without an outlet connection.

The design of the valve inlet can take two forms:

- Full-nozzle designs: Feature a 'wetted' inlet made from a single piece, ideal for process and high-pressure applications, especially with corrosive fluids.

- Semi-nozzle designs: Incorporate a seating ring into the body, allowing for easy seat replacement without replacing the entire inlet.

The core operating mechanism revolves around the interaction between the disc and the nozzle seat. Under normal conditions, the disc is held against the seat by a spring housed in an open or closed spring housing atop the body. Rapid-opening (pop type) safety valves use a shutter around the disc to facilitate swift opening.

The closing force on the disc is exerted by a spring, typically made of carbon steel. The compression on the spring, adjustable with a setting screw, determines the pressure at which the disc lifts off its seat, providing overpressure protection.

Standards governing safety valves focus on defining key dimensions for the valve's discharge capacity, including:

- Flow area: Minimum cross-sectional area between the inlet and seat.

- Curtain area: Area of the discharge opening created by the disc's lift.

- Discharge area: The lesser of the curtain and flow areas, determining the valve's flow capacity.

These dimensions are crucial in ensuring the optimal performance of safety valves in diverse industrial applications.

Curious to discover what types of safety valves there are? Click here!

Operation of safety valves

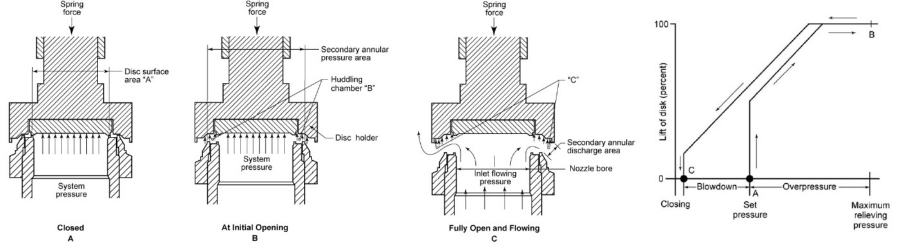

When the inlet static pressure exceeds the set pressure of the safety valve, the valve's disc begins to lift off its seat. The initial audible leaking pressure, referred to as the set pressure, typically adheres to a tolerance of +/- 3% or +/- 0.1 bar, depending on the higher value. As the spring starts to compress, the pressure must rise further before any substantial flow occurs through the valve.

The additional pressure rise needed for the safety valve to discharge at its rated capacity is termed overpressure. This allowable overpressure, defined by standards and application requirements, generally falls within a tolerance of +10% or +0.1 barg, depending on the higher value.

As the valve begins to lift and fluid enters the shutter chamber, a larger area of the shutter becomes exposed to fluid pressure, increasing the opening force. This enhanced opening force counters the rising spring force, enabling the valve to open rapidly.

Simultaneously, the shutter reverses the flow direction, creating a reaction force that further enhances lift. These combined dynamics ensure the valve achieves its designed lift with minimal overpressure.

Once the safety valve has relieved pressure and normal conditions are restored, it must close promptly. However, because of the larger area of the disc still exposed to fluid, the valve remains open until the pressure drops below the set pressure. This differential, known as blowdown, is expressed as a percentage of the set pressure. For compressible fluids, blowdown is typically 15% of the set pressure or the set value minus 0.3 barg, whichever is greater.

The design of the shutter plays a vital role in achieving rapid opening and minimal blowdown, ensuring the valve effectively relieves overpressure while minimizing fluid discharge. Moreover, the design must guarantee sufficient pressure reduction to avoid immediate reopening, balancing safety and operational efficiency.

Certification and approval of safety valves

In many countries, independent organizations play a pivotal role in assessing the design and performance of products to ensure compliance with codes and standards. This third-party approval system is especially common for safety-related products and is often required for purchases or mandated by insurance providers. Examples of such entities include TÜV, Lloyd’s Register, and RINA.

The criteria for approval can vary based on the relevant code or standard. Certain regulations mandate periodic revalidation, while others allow indefinite approval, provided no major design changes occur. In cases of significant modifications, notifying the approval authority and obtaining re-approval is usually necessary.

In the United States, the National Board of Boiler and Pressure Vessel Inspectors ensures compliance with code construction and repairs for boilers and pressure vessels, representing both US and Canadian agencies. In China, the CSEI certifies safety valves under the SELO Chinese pressure equipment regulation. For Europe, adherence to the Pressure Equipment Directive (PED) is essential. Safety valves, classified as 'Safety accessories' under the PED, fall into 'Category 4' equipment, necessitating rigorous assessments to meet the highest level of PED requirements.

These official approval processes are critical for ensuring the safety and reliability of products globally. Each region maintains its own regulations and oversight bodies to uphold industry standards and protect consumer interests.