ATEX-UKEX

ATEX and UKEX Directive

The Directive 2014/34/EU of the European Parliament and the Council, transposed into Italian law through Legislative Decree no. 26 of February 15, 2016, regulates the harmonization of regulations among member states regarding equipment and protective systems used in potentially explosive atmospheres, known as Hazardous Areas. This legislation also encompasses safety, control, and regulation devices intended for use outside hazardous environments, essential for the safe operation of equipment and protection systems, mitigating the risk of explosions. In effect since April 20, 2016, compliance is attested by affixing the CE mark on equipment, systems, and protective devices, ensuring high standards for safety in potentially hazardous settings. With the UK's exit from the European Union, the UK adopted the Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres Regulations 2016, which is equivalent to the provisions of European Directive 2014/34/EU.

Main Criteria to classify the Group of Equipments in Categories

The classification of groups of devices into categories is essential to ensure specific safety standards in potentially explosive environments. Directive 2014/34/EU and the Equipment for Explosive Atmospheres Regulations 2016 provide the criteria for this classification.

Group I Equipment includes two categories:

Category M1 includes devices designed, possibly equipped with special additional protective means, to operate in accordance with the operating parameters established by the manufacturer and ensure a very high level of protection. These devices are intended for underground work in mines and their surface installations exposed to the risk of releasing firedamp and/or combustible dust. Devices in this category must remain operational in an explosive atmosphere, even in the case of exceptional device failure, and must be characterized by protective means such that:

- In the event of a failure of one of the protective means, at least one second independent means ensures the required level of safety.

- In the event of two independently occurring failures, the required level of safety is guaranteed.

Category M2 includes devices designed to operate in accordance with the operating parameters established by the manufacturer and ensure a high level of protection. Devices in this category are intended for underground work in mines and their surface installations exposed to the risk of releasing firedamp and/or combustible dust. In the presence of a potentially explosive atmosphere, the power supply to these devices must be able to be interrupted. The protective means related to devices in this category ensure the required level of protection during normal operation, including under severe operating conditions, especially those resulting from strong stresses and continuous environmental variations.

| GROUP I EQUIPMENT | |

|---|---|

| CATEGORY M1 | CATEGORY M2 |

| Operativity in explosive atmosphere | Non-electrical equipment for explosive atmospheres |

The Group II Equipment is divided into three categories:

Category 1 includes devices designed to operate in accordance with the manufacturer's specified operational parameters and ensure a very high level of protection. Devices in this category are intended for environments where an explosive atmosphere, due to mixtures of air and gases, vapors, mists, or mixtures of air and dust, is always, frequently, or for long periods. Devices in this category must ensure the required level of protection, even in the event of an exceptional device failure, and must be characterized by means of protection such that:

- In the event of a failure of one of the protective means, at least the required level of safety is ensured by a second independent means.

- In the event of two independent failures occurring one after the other, the required level of protection is guaranteed.

Category 2 includes devices designed to operate in accordance with the manufacturer's specified operational parameters and ensure a high level of protection. Devices in this category are intended for environments where there is a probability of explosive atmospheres due to gases, vapors, mists, or mixtures of air and dust. The protective means related to this category must ensure the required level of protection, even in the presence of recurring anomalies or malfunctions of the devices that need to be taken into account.

Category 3 includes devices designed to operate in accordance with the manufacturer's specified operational parameters and ensure a normal level of protection. Devices in this category are intended for environments where there is a low probability of explosive atmospheres due to gases, vapors, mists, or mixtures of air. A Quality Assurance System approved by the competent authority is required for companies producing equipment to be used in potentially explosive atmospheres. Additionally, they will be subject to periodic production inspections.

| GROUP II EQUIPMENT | ||

|---|---|---|

| Device Category | GAS | DUST |

| 1 | Zone 0 | Zone 20 |

| 2 | Zone 1 | Zone 21 |

| 3 | Zone 2 | Zone 22 |

ATEX Zones Description

| Zone 0 | An area in which an explosive atmosphere, consisting of a mixture of air and flammable substances in the form of gas, vapor, or mist, is permanently, frequently, or for long periods present. | |

|---|---|---|

| Zone 20 | Area where an explosive atmosphere, in the form of a cloud of combustible dust in the air, is permanently, frequently, or for long periods present. | |

| Zone 1 | Area where, during normal activities, the formation of an explosive atmosphere, consisting of a mixture of air and flammable substances in the form of gas, vapors, or mist, is likely to occur. | |

| Zone 21 | Area where, occasionally during normal activities, the formation of an explosive atmosphere, in the form of a cloud of combustible dust in the air, is likely to occur. | |

| Zone 2 | Area where, during normal activities, the formation of an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapor, or mist is not likely to occur. If it does occur, it will be of short duration only. | |

| Zone 22 | Area where, during normal activities, the formation of an explosive atmosphere in the form of a cloud of combustible dust is not likely to occur. If it does occur, it will be of short duration only. | |

Safety valves ATEX-UKEX certified

Although safety valves are not electrical or electronic equipment, the ATEX-UKEX directive is still applicable to these safety devices. The relevant legislation for mechanical equipment is BS EN ISO 80079-36 and BS EN ISO 80079-37. These standards address safety requirements for non-electrical equipment used in potentially explosive atmospheres. These devices may include mechanical, hydraulic, pneumatic, or manual elements that could be present in environments where the accumulation of flammable gases or vapors is a risk. The standard establishes specific requirements for the design, manufacture, and safe use of such equipment, including safety valves, helping to mitigate the hazards of explosion in industrial environments. Adhering to these standards is essential to ensure safety and compliance in risk-prone situations.

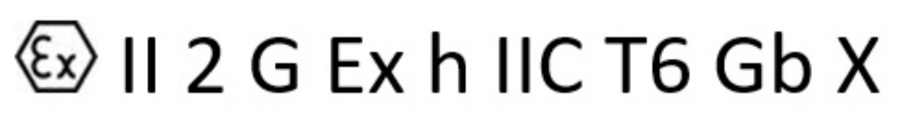

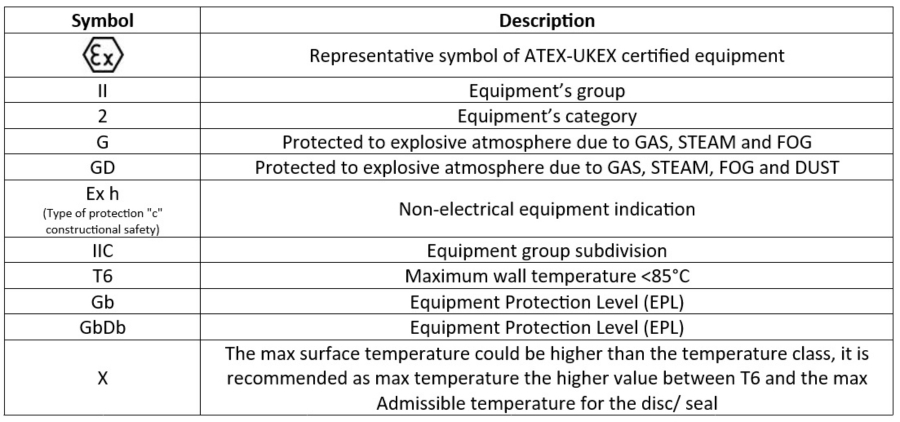

Nuova General Instruments' safety valves, both those with free discharge and those piped with lever, can be ATEX certified only for atmospheres with GAS-MISTS (Equipment Group II – Category 2 – Zone 21 and 22). The marking for these safety valves will be as follows:

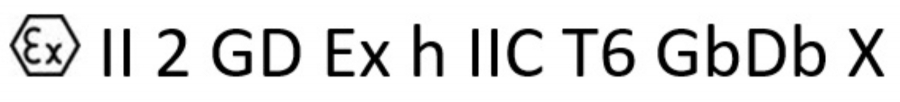

Nuova General Instruments' piped safety valves (excluding those with a lever) can be certified for ATEX atmospheres with GAS-MISTS-DUST (Equipment Group II - Category 2 - Zone 1, 2, 21, and 22).

Nuova General Instruments' free discharge safety valves with aluminium protective hood cannot be ATEX certified.

ATEX and USA Market

Manufacturers of industrial machines designed for use in explosive atmospheres have traditionally focused on electrical ignition sources, aligning with ATEX directives. The transition to new standards, namely EN ISO 80079-36:2016 and EN ISO 80079-37:2016, has clarified requirements, superseding the EN 13463 series. When exporting to the USA, companies have typically adhered to NFPA 70, especially ARTICLE 670 and Chapter 5 Special Occupancies, addressing electrical and electronic equipment in potentially hazardous locations.

A prevailing perception has been that NFPA 70, as the National Electrical Code, does not extend its coverage to mechanical ignition sources. Consequently, manufacturers exporting to the USA may not have felt compelled to consider non-electrical equipment in hazardous locations.

However, recent developments challenge this perception. Despite NFPA 70's electrical focus, the USA's participation in the IECEx International Certification System, encompassing ISO 80079-36 and -37 standards, has triggered a shift. On September 25, 2020, UL CSDS Proposal 80079-36, Edition 1, and 2020 UL CSDS Proposal 80079-37, Edition 1 were unveiled. Though these standards are still in the proposal stage, they indicate a changing landscape, debunking the notion that national standards in the USA exclude non-electrical equipment.

Notably, ISO 80079-36 has already found its place in a US standard – UL 2011 Outline of Investigation for Machinery. The standard, in its fifth edition as of October 13, 2020, references ISO 80079-36 in PART 3 – MACHINERY FOR HAZARDOUS LOCATIONS, clause 77 Normative References.

Moreover, sub-clause 78.1 in UL 2011 emphasizes compliance with explosion risk requirements arising from "non-electrical sources." Examples such as bearings, couplings, pumps, gearboxes, brakes, hydraulic, and pneumatic motors are cited, reminiscent of ISO 80079-36:2016. Intriguingly, despite being in its fifth edition, UL 2011 has not yet referenced Part 37, which supplements ISO 80079-36 by introducing protection types such as constructional safety "c" (applicable for safety valves), control of ignition source "b" and liquid immersion "k".

In summary, the grace period for companies manufacturing mechanical equipment for hazardous locations in the USA may soon conclude. While those experienced in ATEX and IECEx certification are familiar with ISO 80079-36 and ISO 80079-37, exporting to the USA demands a re-evaluation of mechanical ignition sources. The evolving standards underscore the need for due diligence, mirroring the meticulous approach required for compliance with ATEX directives or the IECEx scheme.